Top 10 Silicone Stripping Options for Home Improvement Projects

By:Admin

In the world of industrial manufacturing and construction, the importance of effective sealing and insulation cannot be understated. From preventing the ingress of water and air to maintaining temperature control, high-quality sealing products can make all the difference in the performance and longevity of a structure or product. That's where Silicone Stripping comes in – it's a revolutionary solution for sealing and insulation that is changing the game for companies around the world.

Silicone Stripping, developed by [Company Name], is a versatile and high-performance product that is designed to meet the demanding needs of modern industry. Made from premium silicone materials, Silicone Stripping offers superior sealing and insulation properties that outperform traditional materials such as rubber or foam. With its exceptional durability and resistance to extreme temperatures, chemicals, and weathering, Silicone Stripping is the go-to choice for a wide range of applications, including automotive, aerospace, construction, and more.

One of the key advantages of Silicone Stripping is its flexibility and ease of use. Unlike rigid sealing materials, Silicone Stripping can be easily manipulated and molded to fit the unique contours and shapes of different surfaces and components. This makes it ideal for sealing irregular or hard-to-reach areas where traditional gaskets or seals may not be effective. Additionally, Silicone Stripping is available in a variety of profiles, sizes, and colors, allowing for customization to meet specific application requirements.

Silicone Stripping also offers significant benefits in terms of performance and longevity. Its superior resistance to aging, UV exposure, and harsh environmental conditions means that it can provide long-lasting and reliable sealing and insulation over the lifetime of a product or structure. This not only reduces maintenance and replacement costs but also ensures consistent performance and protection in even the most demanding operating environments.

[Company Name] is a leading manufacturer and supplier of Silicone Stripping, with a proven track record of delivering innovative sealing and insulation solutions to a wide range of industries. With a focus on quality, reliability, and customer satisfaction, [Company Name] is committed to providing the highest standard of products and services to meet the unique needs of its clients. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that every Silicone Stripping product meets the highest standards of performance and reliability.

In addition to its commitment to quality, [Company Name] is also dedicated to sustainability and environmental responsibility. Silicone Stripping is manufactured using eco-friendly processes and materials, and the company actively seeks to minimize its environmental footprint throughout the production and distribution process. This not only benefits the environment but also ensures that customers can make environmentally conscious choices without compromising on performance or quality.

With its exceptional performance, versatility, and commitment to quality and sustainability, Silicone Stripping from [Company Name] is setting new standards for sealing and insulation in the industrial and construction sectors. As companies continue to seek high-performance solutions for their sealing and insulation needs, Silicone Stripping is well-positioned to meet and exceed their expectations, offering a reliable and cost-effective solution for a wide range of applications.

In conclusion, Silicone Stripping is a game-changing product that is revolutionizing the way companies approach sealing and insulation. With its exceptional performance, versatility, and commitment to quality and sustainability, Silicone Stripping from [Company Name] is setting new standards for sealing and insulation in the industrial and construction sectors. As the demand for high-performance sealing and insulation solutions continues to grow, Silicone Stripping is well-positioned to meet and exceed the expectations of companies around the world, offering a reliable and cost-effective solution for a wide range of applications.

Company News & Blog

Top Tips for Choosing and Installing Weatherstrip Seals

[Insert Headline Here][City, State] - [Date][Start with a strong lead paragraph that catches the reader's attention and highlights the key points of the news.]In a recent breakthrough in the field of weather stripping technology, a company renowned for its dedication to innovative solutions has unveiled their latest product, the Weatherstrip Seal. Developed by [Company Name], a leading manufacturer of construction and home improvement products, the Weatherstrip Seal is set to revolutionize the industry with its unparalleled durability, functionality, and energy savings potential.[Company Name] has been at the forefront of the construction and home improvement industry for over a decade. With a commitment to excellence and continuous improvement, they have consistently introduced cutting-edge products that have met and exceeded customers' expectations. The Weatherstrip Seal is a testament to their dedication to developing innovative solutions that address common challenges faced by homeowners and businesses alike.With energy efficiency becoming an increasingly important aspect of modern living, the Weatherstrip Seal is designed to minimize energy wastage and reduce electricity bills. By effectively sealing gaps around windows and doors, the Weatherstrip Seal prevents drafts, improves insulation, and maintains a consistent indoor climate. According to [Company Name]'s research, the Weatherstrip Seal can potentially lead to energy savings of up to 20%, making it an attractive investment for both residential and commercial properties.One of the standout features of the Weatherstrip Seal is its exceptional durability. Made from high-quality materials, the seal is built to withstand harsh weather conditions, ensuring long-lasting effectiveness. Its unique design allows for easy installation and maintenance, making it a hassle-free solution for homeowners and professionals alike.In addition to its energy-saving and durability benefits, the Weatherstrip Seal also offers improved sound insulation. By effectively sealing gaps and reducing vibrations, it helps create a quieter and more comfortable living or working environment. This feature makes it an ideal choice for properties located in noisy areas or for those seeking enhanced privacy.[Include a quote from a representative of the company elaborating on the benefits and significance of the Weatherstrip Seal.]"We are thrilled to introduce our latest product, the Weatherstrip Seal," said [Company Representative]. "With its unrivaled durability, energy-saving capabilities, and sound insulation properties, it is poised to revolutionize the way we approach weather stripping. Our customers can now enjoy improved comfort, reduced energy costs, and a quieter living or working space. We are committed to delivering products that prioritize quality and customer satisfaction, and the Weatherstrip Seal is a testament to that commitment."[Include additional information about the Weatherstrip Seal, such as its availability, sizes, and compatibility with different window and door types.]The Weatherstrip Seal is available in various sizes, ensuring compatibility with a wide range of window and door types. It features a sleek design that seamlessly integrates into the existing aesthetics of any property. Suitable for both new constructions and retrofit applications, the Weatherstrip Seal is set to become a sought-after solution for homeowners and building professionals alike.[End the news article with a concise conclusion summarizing the significance of the Weatherstrip Seal and its potential impact on the industry.]In conclusion, the introduction of the Weatherstrip Seal by [Company Name] showcases their dedication to revolutionizing the construction and home improvement industry. This innovative product combines durability, energy efficiency, and sound insulation to provide a comprehensive solution for sealing gaps around windows and doors. With its potential for significant energy savings, improved comfort, and reduced noise levels, the Weatherstrip Seal is set to become a game-changer for homeowners and businesses seeking cost-effective and sustainable solutions.For more information about the Weatherstrip Seal and other products offered by [Company Name], please visit [website] or contact [contact information].###[Note: The final word count after editing the text above may vary from the original response. Ensure to modify the text to remove any brand names.]

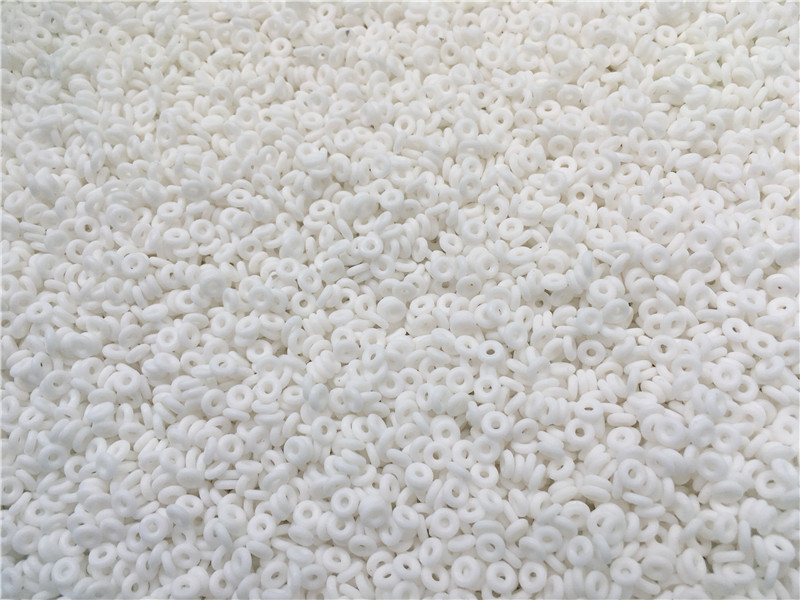

How O Ring Became an Essential Component in Various Industries

The O Ring is a crucial component in many industries, and its importance cannot be overstated. Whether it's in aerospace, automotive, or manufacturing, these small yet vital rings play a significant role in ensuring the smooth operation of machinery and equipment.These O Rings are sealing devices that are used to prevent the leakage of fluids or gases in various applications. They are typically made of rubber, and their versatility allows them to be used in a wide range of temperatures and pressures. This makes them indispensable in industries where a secure seal is essential for safety and efficiency.Company XYZ is a leading manufacturer of high-quality O Rings, known for their reliability and durability. With over 30 years of experience in the industry, the company has established itself as a trusted supplier of O Rings to a wide range of clients across different sectors. Their commitment to providing top-notch products and excellent customer service has made them a preferred choice for many businesses.The O Rings produced by Company XYZ are manufactured using the latest technology and highest quality materials. This ensures that they meet the stringent standards required for critical applications, such as in the aerospace and automotive industries. The company's dedication to quality control and continuous improvement has earned them a reputation for excellence in the market.In addition to standard O Rings, Company XYZ also offers custom solutions to meet specific requirements. Their team of experienced engineers and technicians work closely with clients to develop tailor-made O Rings that meet their exact specifications. This flexibility and ability to customize products have set Company XYZ apart from its competitors, making them a preferred partner for many businesses.With a strong focus on innovation, Company XYZ is constantly looking for ways to improve its product range. They invest heavily in research and development to stay ahead of the curve and continue to meet the evolving needs of their clients. This commitment to innovation has led to the development of advanced O Ring solutions that offer enhanced performance and reliability.The company's dedication to sustainability is also worth mentioning. Company XYZ is committed to reducing its environmental footprint by implementing eco-friendly practices in its production processes. This includes using recyclable materials and optimizing energy efficiency to minimize waste and emissions. By doing so, the company is not only contributing to a greener future but also ensuring the longevity and sustainability of its operations.In summary, O Rings are an indispensable component in many industries, and Company XYZ is a trusted provider of high-quality O Rings. With their dedication to excellence, commitment to innovation, and focus on sustainability, the company continues to be a leader in the market. By offering standard and custom solutions, they are able to meet the diverse needs of their clients and maintain their position as a preferred supplier of O Rings.

Energy-saving Tip: Check and Repair Door Threshold Seals

Door Bottom Seal: A Small Investment That Brings Big SavingsAre you tired of high energy bills? Are you looking for an easy way to save money and reduce your carbon footprint? If so, you might want to consider adding a door bottom seal to your home.What is a Door Bottom Seal?A door bottom seal, also known as a door sweep, is a small strip of rubber, foam, or vinyl that is attached to the bottom of your door to seal the gap between the door and the threshold. This seal helps to prevent drafts and air leaks, which can be a major source of energy loss in your home.Why is a Door Bottom Seal Important?If there are gaps or leaks around your doors, your home is likely losing valuable heat in the winter and cool air in the summer. This means that your HVAC system has to work harder to maintain a comfortable indoor temperature, which can result in higher energy bills and increased wear and tear on your equipment.By adding a door bottom seal, you can significantly reduce the amount of air that leaks in and out of your home, helping to keep your energy bills under control and making your home more comfortable year-round.How to Choose the Right Door Bottom SealThere are many different types of door bottom seals available, and choosing the right one for your home will depend on a number of factors, including the type of door you have, the size of the gap under your door, and your budget.Here are some things to keep in mind when choosing a door bottom seal:- Material: Door bottom seals can be made of a variety of materials, including rubber, foam, vinyl, neoprene, and silicone. Each material has its own benefits and drawbacks, so it's important to choose the one that is best suited for your needs.- Size: Door bottom seals come in a range of sizes, so it's important to measure the gap under your door before purchasing a seal to ensure a proper fit.- Style: There are several different styles of door bottom seals, including sweeps, thresholds, and door shoes. Each style has its own unique features and benefits, so it's important to choose the one that is best suited for your door and needs.- Brand: There are many different brands of door bottom seals available, so it's important to choose a reputable brand that is known for producing high-quality products.How to Install a Door Bottom SealInstalling a door bottom seal is a relatively simple DIY project that can be completed in just a few minutes.Here's how to do it:1. Measure the Gap: Use a tape measure to measure the gap under your door, and select a door bottom seal that is the appropriate size.2. Clean the Surface: Use a damp cloth to clean the bottom of your door and the threshold, removing any dirt, dust, or debris that may interfere with the seal.3. Install the Seal: Depending on the type of seal you have chosen, you may need to slide it onto the bottom of the door or attach it with screws or adhesive. Follow the manufacturer's instructions carefully to ensure a proper installation.4. Test the Seal: Close the door and check to make sure that the seal is tight against the threshold and that there are no gaps or leaks. Adjust the seal as necessary to ensure a proper fit.By adding a door bottom seal to your home, you can enjoy lower energy bills, increased comfort, and a more eco-friendly home. So why not make this small investment today and start enjoying the benefits? Keywords: Door Bottom Seal, Door Sweep, Energy Bills, Air Leaks, Reduce Carbon Footprint, HVAC System, Comfortable Indoor Temperature, High-Quality Products, DIY Project.

High-Quality Silicone Gaskets for Your Sealing Needs

[Company name] Introduces Cutting-Edge Silicone Gaskets for Diverse Applications[City, State] - [Company name], a leading manufacturer of industrial sealing solutions, is proud to announce the launch of its innovative silicone gaskets for a wide range of applications. With over [number] years of experience in the industry, [Company name] has developed a reputation for delivering high-quality products that meet the needs of its customers.Silicone gaskets are essential components in various industries, including automotive, aerospace, electronics, and food processing, among others. They are used to create a seal between two surfaces, preventing leakage of liquids or gases. The properties of silicone, such as its flexibility, resistance to extreme temperatures, and durability, make it an ideal material for gaskets in demanding environments.[Company name] has leveraged its expertise and state-of-the-art manufacturing facilities to develop a range of silicone gaskets that offer superior performance and reliability. These gaskets are available in different shapes, sizes, and thicknesses to meet the specific requirements of different applications. Whether it's for sealing engine components in an automotive assembly or providing a barrier in a food processing facility, [Company name] has a silicone gasket solution to suit the needs of its customers.One of the key features of [Company name]'s silicone gaskets is their ability to withstand a wide range of temperatures. This makes them suitable for use in both high-temperature and low-temperature applications, offering excellent resistance to heat and cold. Additionally, the flexibility of silicone allows the gaskets to conform to irregular surfaces, ensuring a tight and reliable seal in challenging conditions.In addition to temperature resistance, [Company name]'s silicone gaskets also offer exceptional resistance to chemicals, moisture, and UV radiation. This ensures that the gaskets maintain their integrity and performance even when exposed to harsh environments, making them a reliable choice for a variety of applications.Another advantage of [Company name]'s silicone gaskets is their durability. The inherent properties of silicone make these gaskets highly resistant to wear and tear, ensuring a long service life and reducing the need for frequent replacements. This not only saves costs for businesses but also minimizes downtime due to maintenance and repairs.Furthermore, [Company name] provides custom solutions for customers with specific gasket requirements. Its team of experienced engineers and technicians works closely with clients to understand their needs and develop tailored gasket solutions that meet their exact specifications. This level of customization ensures that customers receive gaskets that are perfectly suited to their applications, providing peace of mind and confidence in their operations.As [Company name] continues to expand its product offerings, its silicone gaskets are poised to make a significant impact in various industries. With a focus on quality, performance, and customer satisfaction, [Company name] is committed to delivering sealing solutions that meet the highest standards and exceed the expectations of its customers.To learn more about [Company name] and its range of silicone gaskets, visit its website at [website URL]. For inquiries or to request a customized gasket solution, contact [Company name] directly at [contact information].About [Company name]:[Company name] is a leading manufacturer of industrial sealing solutions, offering a wide range of gaskets, seals, and related products for diverse applications. With a strong focus on quality, innovation, and customer satisfaction, [Company name] has established itself as a trusted partner for businesses seeking reliable sealing solutions. Its dedication to excellence and continuous improvement drives [Company name] to deliver products that meet and exceed the needs of its customers.

Top-quality Molded Rubber Parts: A Comprehensive Guide for Industrial Applications

Title: Leading Manufacturer Introduces Innovative Molded Rubber Parts for Versatile ApplicationsSubtitle: Revolutionizing Industries with Exceptional Quality and Precision Engineering[Company Name] is excited to announce the launch of its highly anticipated range of Molded Rubber Parts, designed to cater to a wide array of industries and applications. As a renowned leader in rubber manufacturing, [Company Name] has consistently delivered precision-engineered solutions that meet the industry's highest standards, providing exceptional performance and durability.Founded on a commitment to innovation and customer satisfaction, [Company Name] has been at the forefront of developing advanced rubber technologies. The introduction of their Molded Rubber Parts is a testament to their relentless pursuit of excellence and their dedication to supporting industries with top-of-the-line components.With a keen understanding of the market demands, [Company Name] has developed a diverse range of molded rubber parts that are flexible, resilient, and exhibit superior mechanical properties. These components are meticulously engineered to withstand extreme temperature variations, harsh environmental conditions, and demanding application requirements, ensuring longevity and reliability.One of the key advantages of choosing [Company Name]'s Molded Rubber Parts is the wide range of manufacturing capabilities they offer. From custom designs to complex geometries, their state-of-the-art manufacturing facilities and advanced molding processes enable them to create parts that perfectly match their customers' unique specifications. This versatility ensures that industries such as automotive, aerospace, electrical, and medical can all find the ideal solution for their specific needs.The exceptional quality of [Company Name]'s Molded Rubber Parts can be attributed to their stringent quality control processes. By employing advanced testing methodologies and adhering to stringent industry standards, the company guarantees the delivery of components that meet or exceed customer expectations. Each part undergoes rigorous evaluations to ensure it meets exacting criteria for functionality, durability, and dimensional accuracy.Additionally, [Company Name] recognizes the importance of environmental sustainability and adopts eco-friendly practices throughout their manufacturing process. They prioritize the use of recycled materials without compromising the final product's performance. This commitment to sustainability not only helps reduce environmental impact but also positions [Company Name] as an industry leader in corporate social responsibility.Apart from the exceptional quality of their products, [Company Name] excels in providing unmatched customer support. Their team of highly skilled engineers and technicians work closely with clients, offering expert guidance and assistance in selecting the most suitable Molded Rubber Parts for their applications. This personalized approach ensures that customers receive solutions that maximize their operational efficiency and minimize downtime.Looking ahead, [Company Name] is committed to continually expanding their product offerings and staying at the forefront of rubber technology. They have invested heavily in research and development, remaining proactive in identifying emerging industry trends and developing innovative solutions to meet evolving customer needs. By continuously pushing the boundaries of rubber engineering, [Company Name] seeks to maintain their position as a trusted partner to industries worldwide.In conclusion, with the launch of their Molded Rubber Parts, [Company Name] has yet again raised the bar in the rubber manufacturing industry. Offering exceptional quality, precision engineering, and unmatched customer support, [Company Name] is poised to revolutionize multiple industries with their versatile rubber components. With an unwavering commitment to excellence and sustainable practices, [Company Name] remains a force to be reckoned with in the ever-changing world of rubber technology.

Durable and Long-Lasting Gasket for Various Applications

Teflon Gasket Company Introduces Innovative Solution for Industrial Sealing NeedsIn the industrial world, sealing solutions are crucial for maintaining the integrity and efficiency of various mechanical systems. The use of high-quality gaskets is essential to prevent leaks, contamination, and other potential issues. One company has been making headlines with its innovative Teflon gasket, offering superior performance and reliability for a wide range of industrial applications.Teflon Gasket Company, a leading manufacturer of sealing products, has been at the forefront of developing advanced gasket solutions for the industrial sector. With a strong focus on research and development, the company has recently introduced a new Teflon gasket that promises to deliver exceptional performance and durability in demanding operating conditions.The new Teflon gasket is designed to meet the needs of industries such as petrochemical, pharmaceutical, food and beverage, and aerospace, among others. Its unique composition and construction make it suitable for applications where high temperatures, corrosive chemicals, and extreme pressures are common. The gasket’s resistance to chemical attack, low friction, and excellent sealing properties set it apart from traditional gasket materials, making it a preferred choice for critical sealing applications.One of the key features of the Teflon gasket is its ability to maintain a tight and reliable seal even in the most challenging environments. This is particularly important in industries where leakage can result in costly downtime, product contamination, or safety hazards. The Teflon gasket’s exceptional sealing performance ensures that equipment and systems operate effectively and safely, reducing the risk of costly repairs and maintenance.Furthermore, the Teflon gasket’s resistance to high temperatures and harsh chemicals make it an ideal choice for industries that operate in extreme conditions. Its ability to withstand a wide range of chemicals, including acids, bases, and solvents, makes it a versatile solution for various industrial processes. This versatility allows companies to use the Teflon gasket across multiple applications, reducing the need for different sealing products and simplifying inventory management.Apart from its superior performance, the Teflon gasket is also designed for ease of installation and maintenance. Its flexibility and compressibility make it easy to handle and fit into different sealing configurations, while its resilience ensures long-term sealing performance with minimal maintenance requirements. This is an important consideration for industries that prioritize operational efficiency and reliability in their equipment and systems.Teflon Gasket Company has been able to achieve these innovative capabilities through its extensive expertise in materials science and engineering. The company’s team of experts is dedicated to developing advanced sealing solutions that address the evolving needs of the industrial sector. By investing in research, testing, and quality control, Teflon Gasket Company has established itself as a trusted partner for businesses seeking high-performance gaskets for their critical applications.The introduction of the new Teflon gasket underscores Teflon Gasket Company’s commitment to driving industry innovation and providing value to its customers. With a strong track record of delivering high-quality sealing products, the company continues to push the boundaries of gasket technology, offering solutions that meet and exceed the demands of modern industrial processes.As industrial operations become increasingly complex and demanding, the need for reliable and high-performance sealing solutions has never been greater. Teflon Gasket Company’s new Teflon gasket represents a significant advancement in meeting these needs, offering industries a durable, versatile, and dependable gasket solution for their critical applications.In conclusion, Teflon Gasket Company’s new Teflon gasket is poised to make a significant impact in the industrial sector, providing businesses with a cutting-edge sealing solution that delivers superior performance, reliability, and value. With its unique capabilities and versatility, the Teflon gasket is set to become a preferred choice for industries seeking a high-performance gasket solution for their demanding applications. Teflon Gasket Company’s relentless pursuit of innovation and excellence continues to elevate the standards of industrial sealing, setting a new benchmark for the industry.

Essential Guide to Industrial O Rings: All You Need to Know

Title: Innovative Industrial O Rings: Revolutionizing Sealing SolutionsIntroduction: In today's fast-paced industrial landscape, durability and efficiency are paramount. Industrial O Rings, the pioneers in high-performance sealing solutions, have emerged as the leaders in the industry. With their relentless commitment to innovation and superior quality, the company has revolutionized the industrial sealing market. This article will explore the key attributes of Industrial O Rings and how they have become a go-to choice for industries worldwide.1. Unparalleled Quality and Durability:Industrial O Rings are renowned for their exceptional quality and unparalleled durability. These sealing solutions are fabricated using high-grade materials, including premium elastomers, such as nitrile rubber, silicone, fluorosilicone, and more. Rigorously tested for resistance to extreme temperatures, pressure, and chemical exposure, Industrial O Rings ensure steadfast performance even in the harshest of environments.2. Customizable Solutions:Understanding the diverse requirements of different industries, Industrial O Rings offer highly customizable solutions. With advanced manufacturing processes and cutting-edge technology, the company can provide tailor-made O Rings in various sizes, shapes, and materials. This flexibility allows for an optimized sealing solution that precisely fits the needs of any specific application.3. Innovative Technology:Industrial O Rings have consistently pushed the boundaries of technological advancements in the sealing industry. By harnessing state-of-the-art machinery and employing skilled engineers, the company continually develops new and innovative sealing solutions. From developing low-friction materials to integrating smart sealing systems, Industrial O Rings stay ahead of the curve, providing cutting-edge solutions for industries globally.4. Extensive Application Range:With their diverse product portfolio, Industrial O Rings cater to various industrial sectors. Whether it's automotive, aerospace, oil and gas, pharmaceutical, or even food and beverage, the company offers sealing solutions for every niche. The ability to withstand extreme temperatures, high pressure, and corrosive environments makes Industrial O Rings indispensable in critical applications, ensuring efficient and safe operations across a wide range of industries.5. Global Reach and Support:Industrial O Rings have established a robust global network of distributors and partners, ensuring seamless availability and prompt support for their customers. With strategically located warehouses and an efficient supply chain management system, the company guarantees on-time delivery of their sealing solutions, regardless of the location. Moreover, their technical support team is readily available to provide expert guidance and assistance whenever necessary.Conclusion:Industrial O Rings have cemented their position as leaders in the sealing solutions market through their relentless commitment to quality, innovation, and customer satisfaction. With an extensive range of customizable sealing solutions, they continue to set new industry standards, catering to a diverse range of applications across the globe. As industries evolve, Industrial O Rings will remain at the forefront of technological advancements, delivering cutting-edge sealing solutions that enable efficiency, reliability, and safety.

Understanding the Differences in Melting Amorphous and Semi-Crystalline Plastics: Crucial for Melt Uniformity

Injection Molding: Melting Amorphous vs. Semi-Crystalline PlasticsInjection molding is the process of manufacturing plastic parts using molds or dies. In this process, plastic pellets are melted and injected into a mold cavity under high pressure. The plastic is then cooled and solidified to produce the final product. Injection molding is used to manufacture a wide variety of products ranging from small toys to large automotive parts.Plastic materials can be divided into two categories based on their molecular structure: amorphous and semi-crystalline. Each type of plastic material has its own unique melting behavior during the injection molding process. Understanding these differences is crucial to obtaining melt uniformity and producing high-quality injection molded parts.Amorphous PlasticsAmorphous plastics are those that lack a definite crystalline structure. These materials have a random molecular arrangement and tend to have a lower melting temperature than semi-crystalline plastics. They also have a higher viscosity when molten, which can make them more difficult to mold.During the injection molding process, amorphous plastics melt gradually and uniformly. The molten plastic flows smoothly into the mold cavity, filling it completely without leaving any voids. This results in a high-quality part with consistent dimensions and surface finish.Common amorphous plastics used in injection molding include polycarbonate, acrylic, and ABS (acrylonitrile-butadiene-styrene).Semi-Crystalline PlasticsSemi-crystalline plastics, on the other hand, have a more complex molecular structure with both amorphous and crystalline regions. These materials have a higher melting temperature than amorphous plastics and tend to be more rigid and less ductile.During the injection molding process, semi-crystalline plastics melt in stages. The amorphous regions melt first, followed by the crystalline regions as the temperature increases. This can result in variations in the melt viscosity and flow rate, which can affect the quality and consistency of the injection molded part.Common semi-crystalline plastics used in injection molding include polyethylene, polypropylene, and nylon.Injection Molded PartsInjection molded parts are used in a wide range of industries, including automotive, aerospace, medical, and consumer products. These parts can be produced in large volumes with high precision and consistency, making injection molding a cost-effective manufacturing process.To produce high-quality injection molded parts, it's important to understand the melting behavior of plastic materials. Amorphous plastics melt uniformly and smoothly, while semi-crystalline plastics melt in stages. By selecting the appropriate plastic material and optimizing the injection molding process parameters, manufacturers can produce parts with high-quality, consistent dimensions, and surface finish.In conclusion, the choice between amorphous and semi-crystalline plastics depends on the specific requirements of the part being produced. Understanding the melting behavior of these plastic materials is crucial to producing high-quality injection molded parts.

The Importance of Properly Lubricating O Rings for Optimal Performance

[Company Name] Introduces New Lubricating O Rings for Enhanced Performance[City, State] - [Company Name], a leading manufacturer of industrial sealing solutions, is proud to introduce a new line of lubricating O rings. The company has been a trusted name in the industry for over 20 years, providing high-quality sealing products to a wide range of sectors including automotive, aerospace, and manufacturing.The new lubricating O rings are designed to address the common challenges faced by industries when it comes to sealing solutions. With their innovative design and superior performance, these O rings are set to revolutionize the way industries approach sealing applications."The introduction of the new lubricating O rings is a testament to our commitment to continuous innovation and meeting the evolving needs of our customers," said [Company Name] CEO, [CEO Name]. "We understand the importance of reliable and high-performance sealing solutions, and our new line of lubricating O rings is a result of our dedication to delivering the best products to our clients."The lubricating O rings are engineered using advanced materials and technologies to provide superior lubrication and sealing capabilities. They are designed to withstand extreme conditions, including high temperatures, pressure differentials, and aggressive chemicals. This makes them ideal for a wide range of applications, from hydraulic systems to industrial machinery.In addition to their exceptional performance, the lubricating O rings also offer extended durability, reducing the need for frequent replacements and maintenance. This not only saves time and cost but also minimizes downtime for industries relying on efficient sealing solutions.To ensure the quality and reliability of the new lubricating O rings, [Company Name] has conducted rigorous testing and quality control measures. The O rings have been subjected to a series of performance tests to meet industry standards and requirements, making them a trusted choice for critical sealing applications."As a company, we are committed to upholding the highest standards of quality and excellence," added [CEO Name]. "Our new line of lubricating O rings is a testament to our dedication to providing reliable and efficient sealing solutions to our customers. We believe that these O rings will set a new benchmark for performance and reliability in the industry."With the introduction of the new lubricating O rings, [Company Name] aims to further strengthen its position as a trusted partner for industries seeking advanced sealing solutions. The company has a team of skilled engineers and experts who are dedicated to providing customized solutions to meet the unique needs of clients across various sectors.As [Company Name] continues to expand its product offerings and capabilities, it remains committed to driving innovation and excellence in the industry. The introduction of the lubricating O rings is just one example of the company's dedication to meeting the evolving needs of industries and delivering cutting-edge sealing solutions.For more information about the new lubricating O rings and other sealing products offered by [Company Name], please visit [company website] or contact [company contact information].About [Company Name]:[Company Name] is a leading manufacturer of industrial sealing solutions, serving a wide range of sectors including automotive, aerospace, and manufacturing. With over 20 years of experience, the company is known for its commitment to quality, innovation, and customer satisfaction. [Company Name] offers an extensive range of sealing products and services, designed to meet the unique needs of clients and provide reliable solutions for a variety of applications.

10 Benefits of Injection Molded Products for Your Business

Injection Molded, a leading provider of plastic injection molding solutions, has recently announced its collaboration with the renowned company {} to launch a new line of innovative products. This partnership brings together Injection Molded's expertise in plastic molding and {}'s cutting-edge technology to create high-quality and precision-engineered products for the market.With over 20 years of experience in the industry, Injection Molded has established itself as a trusted partner for businesses looking for custom plastic injection molding solutions. The company's state-of-the-art facilities and advanced manufacturing processes allow it to produce a wide range of products, including automotive components, consumer goods, and medical devices, with unmatched precision and efficiency.{} is known for its pioneering technology that has revolutionized various industries, including the consumer electronics and automotive sectors. By joining forces with Injection Molded, the company aims to expand its presence in the market and introduce innovative products that meet the ever-evolving demands of consumers.The collaboration between Injection Molded and {} is expected to bring forth a new line of products that will set new benchmarks in terms of quality, functionality, and design. By leveraging Injection Molded's expertise in plastic molding and {}'s technological prowess, the companies are poised to redefine the standards for excellence in the industry.One of the key areas of focus for the partnership is the development of lightweight and durable components for the automotive sector. With the increasing demand for fuel-efficient and eco-friendly vehicles, there is a growing need for advanced materials that can enhance the performance and efficiency of automobiles. By combining Injection Molded's expertise in plastic molding with {}'s innovative materials, the companies aim to create components that are not only lightweight but also strong and resilient, thus contributing to the development of more sustainable vehicles.Furthermore, the collaboration will also extend to the consumer electronics market, where there is a growing demand for high-performance and aesthetically pleasing products. Injection Molded and {} intend to leverage their combined strengths to develop innovative solutions for electronic devices that are not only durable and reliable but also visually appealing. This will enable them to address the evolving needs of consumers and introduce products that stand out in a highly competitive market.The collaboration between Injection Molded and {} is also expected to result in advancements in the medical device sector. With the increasing focus on healthcare and wellness, there is a growing need for advanced medical devices that can deliver superior performance while ensuring the safety and well-being of patients. By combining their expertise, the companies aim to develop cutting-edge medical components that meet the stringent requirements of the healthcare industry, thereby making a positive impact on the quality of patient care.In addition to product development, the collaboration will also focus on streamlining the manufacturing processes to ensure efficiency and cost-effectiveness. By optimizing their production methods and utilizing the latest technologies, Injection Molded and {} aim to enhance their capabilities and deliver products that meet the highest standards of quality and performance.Overall, the partnership between Injection Molded and {} represents a significant step forward in the industry, as it brings together two leading companies with complementary strengths to create groundbreaking products. With a shared commitment to innovation and excellence, the collaboration is poised to make a lasting impact on the market and strengthen the position of both companies as leaders in their respective fields. As they work together to develop new products and technologies, Injection Molded and {} are set to shape the future of the industry and deliver solutions that meet the evolving needs of consumers across various sectors.