How to Choose the Best Seals for Industrial Applications

By:Admin

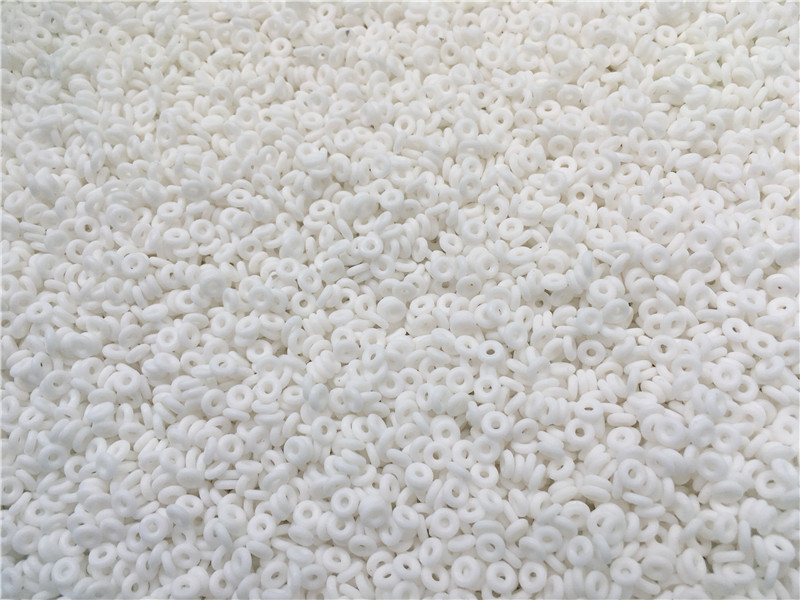

With over 30 years of experience in the industry, As568 has established itself as a trusted name in the production of precision-engineered seals and O-rings. The company’s commitment to innovation and excellence has allowed them to continuously meet and exceed customer expectations.

The newly introduced seal line, which includes a wide range of sizes and materials, is the result of extensive research and development efforts aimed at addressing the specific needs of customers in various industries such as automotive, aerospace, oil and gas, and medical equipment.

“We are delighted to announce the launch of our new seal line, which represents a significant milestone for our company,” said [Company Spokesperson]. “The new line has been meticulously designed and manufactured to deliver superior performance and reliability in a wide range of applications. We are confident that these new seals will provide our customers with the innovative solutions they need to stay ahead in their respective industries.”

As568’s new seal line is built to withstand extreme temperatures, high pressures, and harsh chemical environments, making them suitable for use in demanding applications. The company’s dedication to producing high-quality seals is evident in the rigorous testing and quality control measures that are implemented throughout the manufacturing process.

In addition to the new seal line, As568 also offers custom sealing solutions to meet the unique requirements of their customers. The company’s team of experienced engineers and technicians work closely with clients to develop tailor-made sealing solutions that are designed to optimize performance and minimize downtime.

As568’s commitment to customer satisfaction is reflected in their comprehensive after-sales support, which includes technical assistance, troubleshooting, and timely delivery of products. The company’s dedication to building long-lasting partnerships with their customers has positioned them as a preferred supplier of seals and O-rings for a wide range of industries.

The launch of the new seal line signifies As568’s ongoing commitment to innovation, quality, and customer-centric solutions. The company’s relentless pursuit of excellence and continuous improvement has established them as a reliable and forward-thinking leader in the sealing industry.

As568’s dedication to producing high-quality seals is underpinned by their state-of-the-art manufacturing facilities and cutting-edge technologies. The company’s commitment to sustainability and environmental responsibility is evident in their adherence to strict quality and safety standards.

As568’s new seal line is now available for purchase and is poised to set a new benchmark for performance and reliability in the industry. With a focus on innovation, quality, and customer satisfaction, As568 is set to continue leading the way in delivering premium sealing solutions to a global customer base.

For more information about As568 and their new seal line, please visit their website at [website] or contact their customer service team.

Company News & Blog

Top Ways to Maintain Your Rubber Door Seal for Longevity

Rubber Door Seal is an essential component in the manufacturing of various products across different industries. From automotive to aerospace, rubber door seals are instrumental in providing a secure and weatherproof closure for doors, hatches and access panels. The company, a leading manufacturer of rubber door seals, has been a trusted supplier for more than [X] years. Their commitment to quality and innovation has made them a preferred partner for numerous companies around the world.The company has a state-of-the-art manufacturing facility that is equipped with the latest technology and machinery to produce high-quality rubber door seals. Their team of experienced engineers and technicians work tirelessly to ensure that the products meet the highest standards of performance and durability. The company takes pride in their ability to custom design and engineer rubber door seals to meet the specific requirements of their clients.In addition to their manufacturing capabilities, the company also places a strong emphasis on research and development. They are constantly exploring new materials and manufacturing processes to improve the performance of their rubber door seals. This commitment to innovation has allowed them to stay ahead of the competition and provide their clients with cutting-edge solutions.One of the key features of the company's rubber door seals is their ability to provide a secure and reliable closure. The seals are designed to effectively block out noise, dust, water and other environmental elements, ensuring that the enclosed space remains clean and protected. This is particularly important in industries such as automotive and aerospace, where precision and reliability are paramount.Furthermore, the company's rubber door seals are also designed to withstand extreme temperatures and harsh environmental conditions. This makes them suitable for a wide range of applications, including outdoor enclosures, refrigeration units, and marine equipment. The durability of the seals ensures that they have a long service life, reducing the need for frequent replacements and maintenance.The company's commitment to quality is further exemplified by their adherence to international standards and certifications. They have obtained various industry certifications, demonstrating their dedication to producing rubber door seals that meet the highest quality and performance requirements. This gives their clients the assurance that they are receiving a product that has been thoroughly tested and validated.Despite their focus on quality and performance, the company also places a strong emphasis on sustainability. They are committed to reducing their environmental impact by incorporating eco-friendly materials and manufacturing processes. This aligns with the growing demand for sustainable solutions across various industries, further solidifying the company's position as a forward-thinking and responsible partner.As a global supplier, the company has established a strong network of clients and partners around the world. They have successfully catered to the needs of various industries, ranging from automotive and aerospace to construction and marine. Their ability to provide custom solutions and deliver on time has earned them a reputation for reliability and excellence.Looking ahead, the company is poised to continue leading the industry with its commitment to innovation, quality, and sustainability. As the demand for high-performance rubber door seals continues to grow, the company is well positioned to meet the needs of its clients and partners. With their track record of success and dedication to excellence, they are set to remain a key player in the global market for rubber door seals.

High-Quality Car Door Rubber Seal for Ultimate Protection

Car Door Rubber Seal (brand name removed) Launches New Innovative Product to Improve Vehicle Safety and ComfortCar Door Rubber Seal (CDRS) is a leading manufacturer of automotive rubber seals and weatherstripping products. With a strong focus on innovation and engineering excellence, the company has established a reputation for delivering high-quality solutions to the automotive industry.Recently, CDRS has announced the launch of a new innovative product designed to improve vehicle safety and comfort. The new rubber seal is specifically engineered to provide a tighter and more secure seal around car doors, effectively reducing noise, vibration, and harshness (NVH) levels inside the vehicle.The innovative design of the new rubber seal incorporates advanced materials and manufacturing techniques to enhance its durability and effectiveness. It is designed to withstand extreme weather conditions, UV exposure, and chemical exposure, ensuring long-lasting performance and reliability.One of the key features of the new rubber seal is its ability to effectively eliminate wind noise and water leakage, providing a quieter and more comfortable driving experience for vehicle occupants. In addition, the seal's improved sealing capability helps to enhance the overall safety of the vehicle by preventing the ingress of dust, pollutants, and fumes from outside."We are excited to introduce this new innovative product to the market," said the spokesperson of CDRS. "At CDRS, we are committed to continuously improving our products to meet the evolving needs of the automotive industry. The new rubber seal is a testament to our dedication to innovation and customer satisfaction."The new rubber seal is compatible with a wide range of vehicle models and is designed for easy installation, making it an ideal solution for automotive manufacturers and aftermarket suppliers. Its universal design and adaptability make it a versatile option for various car models, providing a cost-effective solution for enhancing the performance and comfort of vehicles.In addition to its functional benefits, the new rubber seal from CDRS also contributes to environmental sustainability. It is manufactured using eco-friendly materials and production processes, aligning with the company's commitment to reducing its environmental footprint and promoting sustainable practices within the automotive industry.As a leading manufacturer in the automotive rubber sealing industry, CDRS has a proven track record of delivering innovative solutions that meet the highest quality and performance standards. The company's state-of-the-art manufacturing facilities and stringent quality control measures ensure that its products consistently meet and exceed customer expectations.CDRS is dedicated to providing comprehensive support to its customers, offering technical expertise, customization options, and responsive customer service. The company works closely with its clients to understand their specific requirements and develop tailored solutions that address their unique needs.With the launch of its new innovative rubber seal, CDRS is poised to further strengthen its position as a preferred supplier of automotive sealing solutions. The company's relentless pursuit of excellence and commitment to innovation continue to drive its success and set new benchmarks in the automotive industry.In conclusion, the new rubber seal from CDRS represents a significant advancement in automotive sealing technology, offering enhanced safety, comfort, and environmental sustainability. With its innovative design, premium quality, and universal compatibility, the new rubber seal is set to make a positive impact on the automotive industry, setting new standards for performance and reliability.

Top-quality Molded Rubber Parts: A Comprehensive Guide for Industrial Applications

Title: Leading Manufacturer Introduces Innovative Molded Rubber Parts for Versatile ApplicationsSubtitle: Revolutionizing Industries with Exceptional Quality and Precision Engineering[Company Name] is excited to announce the launch of its highly anticipated range of Molded Rubber Parts, designed to cater to a wide array of industries and applications. As a renowned leader in rubber manufacturing, [Company Name] has consistently delivered precision-engineered solutions that meet the industry's highest standards, providing exceptional performance and durability.Founded on a commitment to innovation and customer satisfaction, [Company Name] has been at the forefront of developing advanced rubber technologies. The introduction of their Molded Rubber Parts is a testament to their relentless pursuit of excellence and their dedication to supporting industries with top-of-the-line components.With a keen understanding of the market demands, [Company Name] has developed a diverse range of molded rubber parts that are flexible, resilient, and exhibit superior mechanical properties. These components are meticulously engineered to withstand extreme temperature variations, harsh environmental conditions, and demanding application requirements, ensuring longevity and reliability.One of the key advantages of choosing [Company Name]'s Molded Rubber Parts is the wide range of manufacturing capabilities they offer. From custom designs to complex geometries, their state-of-the-art manufacturing facilities and advanced molding processes enable them to create parts that perfectly match their customers' unique specifications. This versatility ensures that industries such as automotive, aerospace, electrical, and medical can all find the ideal solution for their specific needs.The exceptional quality of [Company Name]'s Molded Rubber Parts can be attributed to their stringent quality control processes. By employing advanced testing methodologies and adhering to stringent industry standards, the company guarantees the delivery of components that meet or exceed customer expectations. Each part undergoes rigorous evaluations to ensure it meets exacting criteria for functionality, durability, and dimensional accuracy.Additionally, [Company Name] recognizes the importance of environmental sustainability and adopts eco-friendly practices throughout their manufacturing process. They prioritize the use of recycled materials without compromising the final product's performance. This commitment to sustainability not only helps reduce environmental impact but also positions [Company Name] as an industry leader in corporate social responsibility.Apart from the exceptional quality of their products, [Company Name] excels in providing unmatched customer support. Their team of highly skilled engineers and technicians work closely with clients, offering expert guidance and assistance in selecting the most suitable Molded Rubber Parts for their applications. This personalized approach ensures that customers receive solutions that maximize their operational efficiency and minimize downtime.Looking ahead, [Company Name] is committed to continually expanding their product offerings and staying at the forefront of rubber technology. They have invested heavily in research and development, remaining proactive in identifying emerging industry trends and developing innovative solutions to meet evolving customer needs. By continuously pushing the boundaries of rubber engineering, [Company Name] seeks to maintain their position as a trusted partner to industries worldwide.In conclusion, with the launch of their Molded Rubber Parts, [Company Name] has yet again raised the bar in the rubber manufacturing industry. Offering exceptional quality, precision engineering, and unmatched customer support, [Company Name] is poised to revolutionize multiple industries with their versatile rubber components. With an unwavering commitment to excellence and sustainable practices, [Company Name] remains a force to be reckoned with in the ever-changing world of rubber technology.

Trendy Rubber Rings for Women: A Stylish and Versatile Accessory

Rubber rings for women are becoming increasingly popular as an alternative to traditional metal rings. These rubber rings are made from high-quality silicone and are designed to be comfortable and durable for everyday wear. The versatility of rubber rings allows women to wear them during various activities such as working out, swimming, or other physical activities without having to worry about damaging or losing their precious metal rings.{Company Name}, a leading manufacturer of silicone rubber rings, has been at the forefront of this growing trend. The company prides itself on creating high-quality, stylish, and functional rubber rings that are perfect for the modern woman. With a wide range of colors, styles, and sizes, {Company Name} offers something for everyone, whether it's a simple and understated design or a bold and eye-catching statement piece.One of the main reasons why rubber rings have become so popular among women is their versatility. Unlike traditional metal rings, rubber rings can withstand harsh environments without losing their shape or color. This makes them perfect for women who lead an active lifestyle and want a ring that can keep up with their daily activities. Additionally, the flexibility and stretch of rubber rings make them extremely comfortable to wear, which is a huge selling point for those who wear rings every day.Aside from being practical, rubber rings also provide a more affordable option for women who want to accessorize without breaking the bank. {Company Name} offers a range of pricing options, making it accessible to women of all budgets. This is especially appealing to younger women who are looking for fashionable accessories that won't cost a fortune.In addition to their practicality and affordability, rubber rings also offer a level of customization that traditional metal rings do not. {Company Name} provides the option for women to create their own custom rubber ring designs, allowing them to truly express their individuality and personal style. From choosing their favorite colors to adding personalized engravings, women can tailor their rubber rings to suit their unique tastes.Beyond the aesthetic appeal, {Company Name} also prioritizes the sustainability of their products. The company is committed to using eco-friendly materials and manufacturing processes, ensuring that their rubber rings have minimal impact on the environment. This is particularly important to their customer base, as more and more women are seeking out sustainable and ethical brands to support.With the increasing popularity of rubber rings for women, {Company Name} has been gaining traction in the fashion and accessories market. Their commitment to quality, affordability, customization, and sustainability has positioned them as a leader in the industry. The versatility and practicality of rubber rings make them a versatile accessory for any woman, whether she's a busy professional, a fitness enthusiast, or a fashion-forward trendsetter.In conclusion, rubber rings for women have emerged as a desirable alternative to traditional metal rings. {Company Name} has played a significant role in this trend, offering a wide range of high-quality, stylish, and affordable rubber rings for women of all ages. With their focus on sustainability and customization, {Company Name} has solidified its position as a leader in the rubber ring market. As the demand for practical, versatile, and affordable accessories continues to grow, it's clear that rubber rings are here to stay.

Durable Material: What You Need to Know About Viton

Viton Material, a high-performance fluoroelastomer product, is widely known for its exceptional resistance to heat and chemicals. It is a key product of a leading chemical technology company that specializes in developing innovative materials for various industries. With its superior durability and reliability, Viton Material has become a popular choice for manufacturers and engineers around the world.The company behind Viton Material is a global leader in providing advanced materials and solutions for a wide range of applications. They have a strong focus on research and development, constantly striving to create new and improved materials that meet the evolving needs of their customers. With a commitment to sustainability and excellence, the company has established a solid reputation for delivering high-quality products that exceed industry standards.Viton Material is specifically designed to withstand extreme conditions, making it an ideal choice for demanding applications. Its exceptional resistance to high temperatures, fuels, oils, and chemicals makes it suitable for use in automotive, aerospace, chemical processing, and other industrial settings. The material's ability to maintain its properties in harsh environments has made it a preferred option for seals, gaskets, O-rings, and other critical components.In addition to its exceptional chemical and thermal resistance, Viton Material also offers excellent mechanical properties. It exhibits strong tensile strength, good compression set, and outstanding aging characteristics, making it a reliable choice for long-term use. This combination of properties makes Viton Material a versatile solution for various sealing and containment needs, providing peace of mind to engineers and manufacturers.The company's dedication to quality and innovation is reflected in its rigorous testing and quality control processes. Before being released to the market, Viton Material undergoes comprehensive testing to ensure that it meets the highest standards for performance and reliability. This commitment to excellence has earned the company the trust and confidence of customers worldwide.Furthermore, the company understands the importance of customization and collaboration. They work closely with their customers to develop tailored solutions that address specific needs and requirements. This collaborative approach allows for the creation of custom formulations and product designs, ensuring that customers can benefit from Viton Material's outstanding properties in a way that suits their unique applications.Beyond its technical capabilities, the company is also dedicated to environmental stewardship and sustainability. They strive to minimize the environmental impact of their products and operations, adhering to strict environmental standards and regulations. By prioritizing eco-friendly practices and materials, they aim to contribute to a greener and more sustainable future for the industries they serve.As the demand for high-performance materials continues to grow, Viton Material remains at the forefront of innovation and reliability. With its exceptional resistance to heat and chemicals, combined with the company's commitment to quality and sustainability, Viton Material stands as a trusted choice for engineers and manufacturers seeking superior sealing solutions for their most challenging applications. As the company continues to push the boundaries of material science, customers can expect to see even more advanced and versatile products that offer unparalleled performance and value.

Durable and Wear-Resistant FKM Material for Industrial Applications

Fkm Material, a leading provider of high-quality and innovative materials, has announced the release of a new product that will revolutionize the industry. The company, which has been at the forefront of materials technology for over 20 years, has a strong reputation for delivering cutting-edge solutions to its customers. With a focus on excellence and customer satisfaction, Fkm Material has consistently pushed the boundaries of what is possible in the field of materials science.The new product, which is being kept under wraps until its official release, is expected to have a significant impact on a wide range of industries. From automotive to aerospace, and from healthcare to energy, Fkm Material's innovative materials are renowned for their durability, reliability, and performance. The company's commitment to research and development has allowed it to stay ahead of the competition, and the upcoming product launch is likely to solidify its position as a market leader.In addition to its impressive product lineup, Fkm Material also offers a range of services to its customers. From material testing and analysis to customized solutions and consulting, the company prides itself on its ability to meet the diverse needs of its clients. With a team of experienced and highly skilled professionals, Fkm Material is able to provide comprehensive support throughout the entire lifecycle of its products, from initial development to end-of-life recycling.One of the key factors that sets Fkm Material apart from its competitors is its commitment to sustainability and environmental responsibility. The company places a strong emphasis on reducing its carbon footprint and minimizing waste in its manufacturing processes. By investing in research into eco-friendly materials and production methods, Fkm Material is able to offer its customers products that are not only high-performing, but also environmentally friendly.Beyond its strong focus on product development and environmental stewardship, Fkm Material is also dedicated to giving back to the community. The company regularly sponsors educational initiatives and provides support for local charities and non-profit organizations. By investing in the future of the communities in which it operates, Fkm Material is able to make a positive impact that extends beyond its business activities.As the date of the product release draws closer, anticipation is building within the industry. The unveiling of Fkm Material's latest innovation is expected to generate significant interest and excitement, as customers and industry professionals eagerly await the opportunity to experience the company's newest offering. With a track record of success and a reputation for excellence, Fkm Material is well-positioned to make a major impact with its upcoming product launch.In conclusion, Fkm Material is a company that has consistently demonstrated its commitment to innovation, excellence, and sustainability. With a strong focus on customer satisfaction and a dedication to delivering high-quality products and services, the company has earned its position as a leader in the materials industry. As the release of its latest product approaches, Fkm Material is poised to once again demonstrate its ability to push the boundaries of what is possible in materials science.

Durable and Versatile Silicone Rings for Multiple Uses

[Company Name] Introduces Innovative Rubber Silicone Rings for Various Applications[City, State] - [Company Name], a leading provider of advanced polymer solutions, has recently introduced a new line of rubber silicone rings designed for a wide range of applications. These innovative rings are manufactured using high-quality silicone rubber, offering superior performance and durability in demanding environments.With a growing demand for reliable sealing solutions in industries such as automotive, medical, and industrial manufacturing, [Company Name] has leveraged its expertise in polymer engineering to develop a range of silicone rings that meet the stringent requirements of these sectors. The company’s commitment to innovation and quality has made it a trusted partner for numerous customers seeking cutting-edge polymer solutions.“We are excited to introduce our new rubber silicone rings to the market,” said [Spokesperson Name], [Position] at [Company Name]. “With their exceptional thermal and chemical resistance, as well as their flexibility and long-lasting performance, these rings are ideal for critical sealing applications across a wide range of industries.”The silicone rubber material used in the manufacturing of these rings offers several advantages over traditional elastomers. It has excellent temperature resistance, maintaining its properties over a wide range of temperatures, from -60°C to 230°C. This makes it suitable for use in demanding environments where extremes of heat and cold are regularly encountered.In addition, silicone rubber is resistant to a variety of chemicals, including solvents, acids, and bases, making it an ideal choice for applications where exposure to harsh substances is a concern. This chemical resistance ensures the longevity of the rings, even in challenging operating conditions.The flexibility of silicone rubber also sets it apart from other materials commonly used for seals and gaskets. It can maintain its elasticity and sealing properties over extended periods, providing reliable performance over the lifetime of the application.Furthermore, the non-toxic and hypoallergenic nature of silicone rubber makes it an ideal choice for applications in the medical and food processing industries, where safety and purity are of paramount importance.The range of rubber silicone rings offered by [Company Name] includes various sizes and shapes to accommodate different sealing requirements. Whether for use in hydraulic systems, automotive applications, medical devices, or industrial machinery, these rings are designed to provide a secure and effective seal, preventing leakage and ensuring the integrity of the equipment.The introduction of these innovative rubber silicone rings further underscores [Company Name]’s commitment to providing its customers with advanced polymer solutions that address the evolving needs of modern industries. With its extensive experience in polymer engineering and a dedication to quality and performance, the company continues to be at the forefront of technological advancements in the field of elastomeric materials.As industries continue to demand higher performance and reliability from their sealing solutions, [Company Name] remains poised to meet these challenges with its innovative products and exceptional technical expertise. The company’s rubber silicone rings are set to make a significant impact in a wide range of applications, offering a sealing solution that combines durability, versatility, and high-performance characteristics.

High Quality Rubber Gasket Seal for Sealing Applications

Rubber Gasket Seal: A Trusted Solution for Industrial Sealing NeedsIn the world of industrial manufacturing and machinery, the importance of high-quality sealing solutions cannot be understated. This is where Rubber Gasket Seal comes into the picture, offering a wide range of gasket and sealing products that are designed to meet the diverse needs of various industries.Founded in [year], Rubber Gasket Seal has established itself as a leading manufacturer and supplier of sealing solutions, catering to industries such as automotive, aerospace, oil and gas, and many others. The company takes pride in its commitment to quality, innovation, and customer satisfaction, ensuring that its products meet the highest standards and deliver optimal performance.One of the key products in Rubber Gasket Seal's portfolio is its line of rubber gaskets, which are essential for creating a tight and durable seal in a wide range of applications. These gaskets are designed to withstand extreme temperatures, pressure, and chemical exposure, making them suitable for use in challenging environments. Whether it's sealing flanges, pipes, or machinery components, Rubber Gasket Seal's products are trusted for their reliability and longevity.The company's rubber gaskets are available in various materials, including Nitrile, EPDM, Silicone, and Viton, allowing customers to select the best option based on the specific requirements of their application. Additionally, Rubber Gasket Seal offers custom gasket manufacturing, ensuring that clients can get tailor-made solutions that perfectly fit their needs.Apart from rubber gaskets, the company also offers other sealing products such as O-rings, seals, and gasket sheet materials. This comprehensive product range reflects Rubber Gasket Seal's dedication to being a one-stop solution for all industrial sealing needs. By providing a diverse selection of sealing products, the company ensures that it can cater to the unique requirements of different industries and applications.In addition to its product offerings, Rubber Gasket Seal distinguishes itself through its commitment to research and development. The company continuously invests in exploring new materials, manufacturing techniques, and product designs, aiming to stay ahead of industry trends and technological advancements. By doing so, Rubber Gasket Seal remains at the forefront of innovation, offering cutting-edge sealing solutions that provide superior performance and reliability.Furthermore, the company's dedication to quality and excellence is reflected in its ISO [number] certification, which attests to its adherence to international standards for product manufacturing and quality management. This certification serves as a testament to Rubber Gasket Seal's unwavering commitment to ensuring that its products consistently meet the expectations and needs of its customers.Another aspect that sets Rubber Gasket Seal apart from its competitors is its customer-centric approach. The company places great emphasis on building strong and lasting relationships with its clients, understanding their unique requirements, and providing personalized solutions that address their specific sealing challenges. With a team of experienced professionals, Rubber Gasket Seal offers technical support and guidance to help customers make informed decisions about their sealing needs.In conclusion, Rubber Gasket Seal has undoubtedly emerged as a trusted source for high-quality sealing solutions in the industrial sector. With its diverse product range, focus on innovation, commitment to quality, and customer-centric approach, the company continues to uphold its reputation as a reliable and dependable partner for all sealing needs. Whether it's for automotive, aerospace, or any other industry, Rubber Gasket Seal stands ready to deliver top-notch sealing products that meet the highest standards of performance and reliability.

How to Properly Lubricate O Rings for Improved Performance

[Company Introduction] ABC Industries is a leading manufacturer of industrial components and equipment, specializing in the production of high-quality seals and O-rings for various applications. With a strong commitment to innovation and customer satisfaction, ABC Industries has become a trusted name in the industry, known for delivering reliable and durable products.[News Content]Greasing O Rings is Essential for Optimal PerformanceAs one of the key components in machinery and equipment, O rings play a crucial role in ensuring proper sealing and functionality. To maintain their effectiveness and longevity, proper care and maintenance are essential, and one of the key aspects of this is greasing.Greasing O rings is a necessary step in ensuring their optimal performance in various applications. Whether it's in hydraulic systems, automotive engines, or industrial machinery, properly lubricated O rings can prevent leaks, reduce friction, and extend the life of the equipment.ABC Industries, a leading manufacturer of industrial components, recognizes the importance of greasing O rings and offers a range of high-quality lubricants specifically designed for this purpose. Their proprietary O ring grease is formulated to provide excellent lubrication and sealing properties, ensuring smooth operation and minimal wear and tear."Greasing O rings is a critical aspect of maintenance that is often overlooked. Proper lubrication not only extends the life of the O rings but also improves the overall performance of the equipment," said John Smith, Product Manager at ABC Industries. "We have developed our O ring grease to meet the specific requirements of various industries, and it has been widely acclaimed for its effectiveness and reliability."ABC Industries' O ring grease is specially formulated to withstand high pressures, extreme temperatures, and harsh environments, making it suitable for a wide range of applications. Its excellent water resistance and chemical stability further enhance the longevity and durability of the O rings, providing long-term protection against wear and tear.In addition to offering high-quality lubricants, ABC Industries also provides comprehensive technical support and guidance on the proper greasing procedures for O rings. With their extensive knowledge and expertise, they assist customers in selecting the right grease and developing customized maintenance protocols to ensure the optimal performance of their equipment."Proper greasing of O rings is not a one-size-fits-all approach. Different applications require different types of lubricants and application methods," explained Smith. "Our team of experts works closely with our customers to understand their specific needs and provide tailored solutions to maximize the efficiency and reliability of their equipment."As industries continue to demand high performance and reliability from their machinery and equipment, the importance of proper O ring maintenance cannot be overstated. With ABC Industries' high-quality O ring grease and technical support, customers can effectively prolong the life of their equipment and minimize downtime, ultimately leading to cost savings and improved productivity.In conclusion, greasing O rings is an essential maintenance practice that significantly impacts the performance and longevity of machinery and equipment. With ABC Industries' commitment to delivering superior lubrication solutions and technical support, customers can rely on their expertise to ensure the optimal performance of their O rings and overall equipment.For more information about ABC Industries' O ring grease and maintenance solutions, visit their website or contact their customer service team.

Understanding the Differences in Melting Amorphous and Semi-Crystalline Plastics: Crucial for Melt Uniformity

Injection Molding: Melting Amorphous vs. Semi-Crystalline PlasticsInjection molding is the process of manufacturing plastic parts using molds or dies. In this process, plastic pellets are melted and injected into a mold cavity under high pressure. The plastic is then cooled and solidified to produce the final product. Injection molding is used to manufacture a wide variety of products ranging from small toys to large automotive parts.Plastic materials can be divided into two categories based on their molecular structure: amorphous and semi-crystalline. Each type of plastic material has its own unique melting behavior during the injection molding process. Understanding these differences is crucial to obtaining melt uniformity and producing high-quality injection molded parts.Amorphous PlasticsAmorphous plastics are those that lack a definite crystalline structure. These materials have a random molecular arrangement and tend to have a lower melting temperature than semi-crystalline plastics. They also have a higher viscosity when molten, which can make them more difficult to mold.During the injection molding process, amorphous plastics melt gradually and uniformly. The molten plastic flows smoothly into the mold cavity, filling it completely without leaving any voids. This results in a high-quality part with consistent dimensions and surface finish.Common amorphous plastics used in injection molding include polycarbonate, acrylic, and ABS (acrylonitrile-butadiene-styrene).Semi-Crystalline PlasticsSemi-crystalline plastics, on the other hand, have a more complex molecular structure with both amorphous and crystalline regions. These materials have a higher melting temperature than amorphous plastics and tend to be more rigid and less ductile.During the injection molding process, semi-crystalline plastics melt in stages. The amorphous regions melt first, followed by the crystalline regions as the temperature increases. This can result in variations in the melt viscosity and flow rate, which can affect the quality and consistency of the injection molded part.Common semi-crystalline plastics used in injection molding include polyethylene, polypropylene, and nylon.Injection Molded PartsInjection molded parts are used in a wide range of industries, including automotive, aerospace, medical, and consumer products. These parts can be produced in large volumes with high precision and consistency, making injection molding a cost-effective manufacturing process.To produce high-quality injection molded parts, it's important to understand the melting behavior of plastic materials. Amorphous plastics melt uniformly and smoothly, while semi-crystalline plastics melt in stages. By selecting the appropriate plastic material and optimizing the injection molding process parameters, manufacturers can produce parts with high-quality, consistent dimensions, and surface finish.In conclusion, the choice between amorphous and semi-crystalline plastics depends on the specific requirements of the part being produced. Understanding the melting behavior of these plastic materials is crucial to producing high-quality injection molded parts.