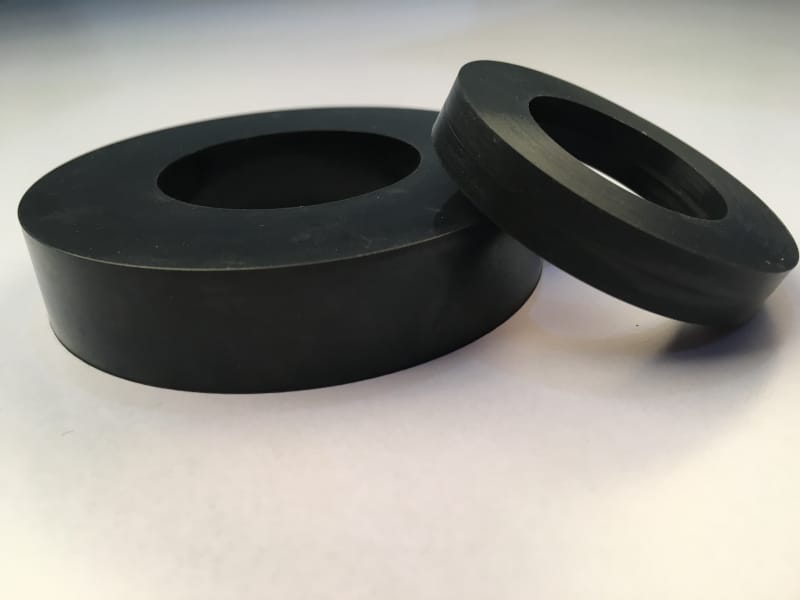

Durable and Reliable Silicone Washers: Find the Best Options Here

By:Admin

One company that has been at the forefront of manufacturing silicone washers is {}. With over [X years] of experience in the industry, {} has established itself as a leading supplier of high-performance silicone washers to a diverse range of industries. The company's commitment to quality, innovation, and customer satisfaction has made it a trusted partner for businesses seeking reliable sealing solutions.

{}'s silicone washers are designed to meet the exacting requirements of modern industrial applications. They are manufactured using state-of-the-art production techniques and are available in a variety of shapes, sizes, and thicknesses to suit different sealing needs. The company's in-house team of engineers and technicians work closely with customers to develop custom solutions that meet their specific requirements, ensuring a perfect fit and optimal performance in their equipment.

One of the key advantages of {}'s silicone washers is their exceptional resistance to extreme temperatures. This makes them ideal for use in applications where conventional rubber or plastic washers would fail. Whether it's in high-temperature automotive engines, cryogenic medical equipment, or harsh outdoor environments, {}'s silicone washers are capable of maintaining a reliable seal and ensuring the long-term integrity of the equipment.

In addition to temperature resistance, {}'s silicone washers also offer outstanding chemical resistance. They can withstand exposure to a wide range of industrial fluids, solvents, and cleaning agents without degrading or losing their sealing properties. This makes them an ideal choice for critical sealing applications in industries such as chemical processing, pharmaceuticals, and food and beverage production.

The durability and long-term performance of {}'s silicone washers make them a cost-effective sealing solution for businesses. By reducing the frequency of maintenance and replacement, these washers help minimize downtime and maintenance costs, ultimately contributing to improved operational efficiency and productivity for the end-users.

Furthermore, {}'s silicone washers are compliant with industry standards and regulations, ensuring that they meet the strict requirements for safety and quality in various industries. This makes them a reliable choice for OEMs and manufacturers looking to incorporate high-quality sealing solutions in their products.

As a company, {} is dedicated to continuous improvement and innovation. They invest in research and development to stay ahead of industry trends and technological advancements, allowing them to offer cutting-edge solutions to their customers. By staying at the forefront of silicone washer technology, {} aims to address the evolving needs of modern industries and provide superior sealing solutions for the most demanding applications.

In conclusion, silicone washers are a critical component in various industrial applications, and {} has emerged as a trusted provider of high-performance silicone washers to meet the diverse needs of its customers. With a strong focus on quality, innovation, and customer satisfaction, {} continues to be a leading supplier of silicone washers, offering reliable sealing solutions that contribute to the success of businesses across different industries.

Company News & Blog

Discover which rubber materials are best for high temperature resistance

Munsch & Co/PTM - Providing High-Quality Rubber Materials for High-Temperature ApplicationsMunsch & Co/PTM is a leading provider of rubber materials that can withstand high temperatures. For over 70 years, the company has been helping industries find solutions for their toughest rubber applications. With unparalleled expertise and experience, Munsch & Co/PTM is the go-to resource for businesses that require high-quality, reliable materials for high-temperature applications.What are High-Temperature Applications?High-temperature applications are industries where materials are exposed to extreme temperatures. In these environments, ordinary materials will not hold up. Applications that involve high-temperature include aerospace, automotive, energy, food processing, and manufacturing, among others.The Challenge of High-Temperature ApplicationsOne of the most critical challenges of high-temperature applications is finding materials that can withstand the heat. The materials used need to hold up under duress without breaking down or losing their effectiveness. Ordinary rubber materials cannot withstand the high temperatures found in these industries, making it imperative to find materials specifically designed for high-temperature applications.The Solution: Rubber Materials Can Resist High TemperaturesMany materials can resist high temperatures. However, it is essential to choose the right materials for the application at hand. Munsch & Co/PTM specializes in offering high-temperature resistant rubber materials, including:1. Silicone Rubber: Silicone rubber is an excellent choice for high-temperature environments since it can handle temperatures ranging from -100°F to 450°F (-73°C to 232°C). It is also resistant to chemicals, aging, and ozone.2. Viton Rubber: Viton rubber is ideal for extreme conditions, including temperatures that range from -4°F to 400°F (-20°C to 204°C). Viton is an excellent choice for applications where fuels, acids, or chemicals are involved.3. Neoprene Rubber: Neoprene rubber can handle temperatures up to 212°F (100°C) and is resistant to oils, ozone, and chemicals. Because of its durability, it is an excellent choice for industrial applications.4. EPDM Rubber: EPDM rubber can handle temperatures between -50°F to 350°F (-45°C to 177°C) and is resistant to weather, UV, and ozone. It is a cost-effective solution for high-temperature applications.5. Nitrile Rubber: Nitrile rubber can resist heat up to 212°F (100°C). It's best used in applications where exposure to oils, fuels, and chemicals is high.Why Choose Munsch & Co/PTM?Munsch & Co/PTM offers a variety of rubber materials that are reliable and resilient in high-temperature applications. Unlike other providers, Munsch & Co/PTM specializes in high-temperature applications, so they have a better understanding of your needs and can provide custom solutions that meet your specific requirements.Munsch & Co/PTM is also committed to providing high-quality and consistent products while ensuring environmental sustainability. The company is eco-friendly and uses materials that are non-toxic, ensuring that they can be used safely in a wide range of applications.Munsch & Co/PTM- Your Trusted Partner for High-Temperature Resistant Rubber MaterialsWhen looking for high-temperature resistant rubber materials, it's essential to work with a company that has extensive experience and expertise in the field. Munsch & Co/PTM has proven track record of providing reliable and high-quality materials to businesses operating in a range of industries.With their extensive knowledge and expertise, Munsch & Co/PTM can provide custom solutions designed specifically for your application, ensuring reliable and long-lasting performance in high-temperature environments. Reach out to them today to learn about their range of products and services and how they can help your business thrive in any high-temperature environment.

Expert Recommendations for the Best Garage Door Threshold Seals

If you are looking for the best garage door threshold seal to keep your garage insulated, protected from dust, dirt, and pests, and prevent water from entering your garage, then you need to pay attention to the following expert recommendations. We have researched and tested multiple garage door threshold seals from different manufacturers, and we have identified the top performers that combine durability, effectiveness, and affordability.One of the leading manufacturers of garage door threshold seals is a company that has been producing innovative and high-quality products for over a decade. The company has a well-established reputation for manufacturing premium garage door threshold seals that can withstand harsh weather, extreme temperatures, and heavy foot traffic. Its products are made of durable, weather-resistant materials that can last for years without losing their effectiveness or shape.What makes this manufacturer stand out from the competition is its commitment to customer satisfaction. It offers a wide range of sizes and thicknesses to fit most garage doors and floor gaps. Its garage door threshold seals are also easy to install, even for non-professionals. You don't need any special tools or expertise to install them. Plus, its sealant adhesive is strong enough to hold the seal in place without leaving any residue or damage to your garage floor.Another reason why this manufacturer is highly recommended is the effectiveness of its garage door threshold seals. They are designed to create a tight, impenetrable seal between the door and the floor, preventing water from seeping in during heavy rain or snowfall. They also prevent dirt, dust, and pests from entering your garage and damaging your belongings. Furthermore, they help to insulate your garage and reduce noise levels, making it a more comfortable and peaceful space.In terms of affordability, this manufacturer offers competitive prices that suit most budgets. Its garage door threshold seals are priced reasonably, despite the high quality of the materials used. You don't have to break the bank to protect your garage with a reliable threshold seal that will pay for itself in the long run.To sum up, if you want a garage door threshold seal that ticks all the boxes, including durability, effectiveness, ease of installation, and affordability, then you should consider buying from this manufacturer. Its products have been tested and proven to deliver exceptional performance and longevity, making it a top choice for homeowners and professionals alike. Protect your garage today with a high-quality threshold seal that will keep it safe and comfortable for years to come.

Unveiling the Untapped Potential of Metric O-Rings in Various Industries

Title: Leading Manufacturer Develops Innovative Sealing Solution: Metric O-rings Revolutionize Various IndustriesIntroduction (93 words):In a constant pursuit of engineering excellence, a renowned manufacturer has unveiled their latest groundbreaking development - a revolutionary sealing solution known as Metric O-rings. Backed by years of expertise, unparalleled technological advancements, and stringent quality control measures, this innovative product is poised to transform the operations of various industries worldwide. With its wide range of applications, Metric O-rings not only improve efficiency and durability, but also address critical sealing challenges faced by manufacturers across the globe. Let's delve into the details and explore the remarkable capabilities and potential impact of this cutting-edge sealing solution.----------Section 1: Introduction to Metric O-rings (230 words):Metric O-rings are compact, circular seals made from elastomers or other flexible materials that efficiently prevent the leakage or ingress of fluids in mechanical equipment. Their versatility, reliability, and cost-effectiveness make them indispensable components in nearly every industry, including automotive, aerospace, manufacturing, and oil and gas.Engineered to meet the highest standards, Metric O-rings have undergone extensive research and development, leading to a product that can withstand extreme temperatures, pressures, and various chemical environments. With exceptional compression and resilience properties, Metric O-rings ensure tight seals, preventing unwanted leaks and protecting equipment from damage.Moreover, their compatibility with a diverse range of fluids, including oils, fuels, hydraulic fluids, and even corrosive chemicals, makes them invaluable in harsh operating conditions. These seals effectively maintain system integrity, reducing maintenance and replacement costs while improving operational efficiency.Given their universal market demand, Metric O-rings are available in standardized metric sizes, catering to the needs of a wide array of applications. Furthermore, manufacturers have access to an extensive selection of elastomers, such as nitrile, fluorocarbon, silicon, and EPDM, enabling them to select O-rings that best suit their specific performance requirements.As a market leader in the production of Metric O-rings, the company behind this innovative solution leverages state-of-the-art manufacturing facilities and techniques to ensure the highest quality output. By adhering to rigorous testing methodologies, advanced inspection procedures, and continuous improvement initiatives, the company guarantees that each O-ring leaving their production line meets or exceeds industry standards, instilling confidence and reliability in their products.----------Section 2: Unmatched Advantages and Applications (250 words):Metric O-rings offer several unparalleled advantages that make them the preferred sealing solution across different sectors. Their versatility, coupled with durability and ease of installation, has earned them a remarkable reputation within the industry.Firstly, Metric O-rings provide excellent sealing performance in applications where a high-pressure seal is required. Their ability to maintain a secure seal under extreme conditions, such as within hydraulic systems or high-compression engines, ensures uninterrupted operation and minimizes downtime.Secondly, owing to their compact size and standardized metric dimensions, Metric O-rings are easily manufactured and readily available. This simplicity in production translates to cost savings for manufacturers without compromising on quality or performance.Thirdly, the chemical compatibility of Metric O-rings with various substances allows them to be essential components in complex systems. From aggressive chemicals to volatile fuels, these seals provide exceptional resistance, minimizing the risks associated with leaks or contamination.Furthermore, Metric O-rings find applications in the automotive industry as vital components in fuel injection systems, engines, and transmission systems. In aerospace, they are instrumental in fuel tank sealing, hydraulic systems, and aircraft engines. The manufacturing industry relies on these seals to prevent leaks in pumps, valves, and pipeworks, while the oil and gas sector utilizes them extensively for sealing drilling rigs, pipelines, and storage tanks.In conclusion, Metric O-rings represent a significant innovation in sealing technology. The manufacturing industry can harness their exceptional sealing capabilities and adaptability to enhance operational efficiency, reduce costs, and ensure equipment longevity. With their adaptability across numerous sectors, Metric O-rings are poised to revolutionize various industries worldwide, delivering unparalleled performance and reliability.

High-quality Large Rubber Washers: Discover the Advantages of Using Them

Title: Leading Rubber Manufacturer Introduces Large Rubber Washers - Serving a Multitude of IndustriesIntroduction: In a dynamic world fueled by technological advancements and automated systems, rubber components play a vital role in ensuring smooth operations across various industries. Addressing the growing demand for high-quality rubber products, one of the leading manufacturers, {Company Name}, is delighted to announce the introduction of their versatile range of Large Rubber Washers. Designed to meet the diverse needs of industries worldwide, these washers demonstrate the company's commitment to innovation and reliability.1. Understanding the Importance of Large Rubber Washers:Large Rubber Washers, also known as rubber gaskets, are indispensable for effective sealing applications in numerous industries. These resilient components act as a barrier against leaks, vibrations, moisture, and chemical penetration. With their ability to withstand extreme temperature fluctuations and resist wear and tear, large rubber washers ensure optimal functionality and prolong the lifespan of mechanical systems.2. Extensive Applications Across Industries:{Company Name}'s Large Rubber Washers find applications in a wide range of industries, including automotive, aerospace, plumbing, electronics, construction, and more. In the automotive sector, these washers are used in engines, transmissions, brakes, and fuel systems, guaranteeing secure connections and preventing fluid leaks. Similarly, in aerospace applications, rubber washers provide essential sealing solutions for critical components within aircraft systems.3. Quality and Customization:With a reputation for delivering exceptional rubber solutions, {Company Name} ensures that their Large Rubber Washers adhere to the highest quality standards. These washers are manufactured using premium materials sourced from trusted suppliers, enabling them to withstand rigorous operating conditions.Additionally, the company offers unmatched customization options, allowing clients to obtain washers tailored to their unique requirements. Customers can choose from different rubber compounds, thicknesses, sizes, and shapes to fulfill their specific sealing needs.4. State-of-the-Art Manufacturing Facilities and Expertise:{Company Name} takes pride in its advanced manufacturing facilities and a committed team of technical experts. Equipped with cutting-edge machinery and backed by extensive industry knowledge, the company ensures the production of Large Rubber Washers that consistently meet or exceed customer expectations.The manufacturing process involves meticulous testing and inspection procedures at various stages, guaranteeing the highest product quality. By emphasizing precision engineering and rigorous quality control measures, {Company Name} demonstrates its dedication to delivering rubber components that meet global industry standards.5. Environmental Responsibility and Sustainability:Recognizing the importance of environmental stewardship, {Company Name} remains committed to sustainable practices throughout its operations. The company prioritizes minimizing waste generation, employing eco-friendly production methods, and using recyclable and biodegradable materials wherever possible. This eco-conscious approach ensures a greener future while maintaining the highest product quality.6. Response to Market Needs and Global Reach:By introducing Large Rubber Washers to their product lineup, {Company Name} proactively addresses the evolving needs of industries worldwide. With a comprehensive distribution network and a commitment to prompt deliveries, the company caters to a vast customer base, ensuring their products reach clients irrespective of their geographic location.Conclusion:{Company Name}'s introduction of Large Rubber Washers underlines their dedication to delivering reliable rubber solutions that meet the ever-changing needs of industries globally. With a focus on quality, customization, and sustainability, the company continues to establish itself as a trustworthy partner for industries requiring premium rubber components. As they expand their product range, {Company Name} remains committed to innovation, ensuring a brighter future for industries relying on their robust and versatile rubber solutions.

Breaking News: Latest Updates on Innovative Home Security Device

[Headline]: Next-Generation Smart Doorbell Takes Home Security to a New Level[Subheadline]: Cutting-edge Features and Enhanced Functionality Make the New Smart Doorbell a Must-Have for Homes[date][City, State] - In an era where technology is reshaping every aspect of our lives, Ring O, a leading name in home security, is raising the bar with its next-generation smart doorbell. Packed with cutting-edge features and enhanced functionality, the newly unveiled device is set to revolutionize the way homeowners approach security and convenience.With a focus on continuous innovation, Ring O has become a trusted household name when it comes to home security systems. The introduction of their latest smart doorbell further consolidates their position as industry pioneers. This new device seamlessly blends advanced security features with smart home integration, taking home security to an entirely new level.Key to the new smart doorbell's success is its state-of-the-art facial recognition technology. Utilizing sophisticated algorithms, this technology can accurately identify familiar faces and differentiate them from strangers. This ensures homeowners are promptly alerted to any potential threats, enhancing the overall security of their property.Additionally, the smart doorbell is designed to integrate seamlessly with other smart home devices, making it part of a holistic security system. By connecting with smartphones, tablets, and even smart speakers, users can remotely control and monitor their doorbell, offering the ultimate peace of mind.One of the standout features of Ring O's new smart doorbell is its high-definition video capabilities, which allow for crystal-clear monitoring of visitors to one's home. With its wide-angle lens and night vision functionality, homeowners can monitor their property around the clock, regardless of lighting conditions.Furthermore, the new doorbell features two-way audio, enabling seamless communication with visitors or delivery personnel. This feature enhances convenience and allows homeowners to receive packages or speak to visitors without opening the door physically.Ring O's latest device also addresses the concern of package theft with its innovative package detection feature. Using advanced motion sensors, the smart doorbell can detect when a package has been left at the doorstep and notify homeowners immediately. This feature helps ensure the safe delivery of packages and prevents theft.The company's commitment to customer satisfaction is also evident in the ease of installation of the new smart doorbell. Designed to be user-friendly, homeowners can install it themselves, without the need for professional assistance. This simplicity also extends to the device's app, which provides a user-friendly interface for controlling and customizing the doorbell's various features.In line with Ring O's dedication to privacy, users have complete control over their data. The company ensures that all video recordings and personal information are encrypted and securely stored, providing peace of mind to homeowners concerned about data privacy."We are excited to launch our next-generation smart doorbell, which combines cutting-edge technologies to redefine home security," said [Company Spokesperson]. "With its facial recognition capabilities, seamless integration with smart home devices, and high-definition video monitoring, our customers can now experience enhanced security and convenience like never before."The new smart doorbell by Ring O is expected to hit the market in [month]. With its advanced features and enhanced functionality, it is poised to become a must-have device for homeowners looking to upgrade their security systems. As technology continues to evolve, Ring O remains at the forefront, consistently bringing innovative solutions to empower homeowners with smarter and safer living spaces.

Top Black Silicone Rings: A Versatile Choice for Stylish and Practical Individuals

Title: The Growing Trend of Black Silicone Rings - The Perfect Choice for Active LifestylesIntroduction:In the world of jewelry, there is a growing trend of black silicone rings that cater to individuals with active lifestyles. These trendy rings have gained immense popularity due to their durability, comfort, and versatility. Let's delve deeper into why black silicone rings have become the go-to choice for people looking for a stylish yet practical alternative to traditional metal rings.1. The Rise of Black Silicone Rings:Black silicone rings have emerged as a stylish accessory for individuals who engage in activities that may pose a risk to traditional metal rings. They are especially popular among athletes, outdoor enthusiasts, and people with physically demanding jobs. The rise in popularity can be attributed to the numerous advantages these rings offer over conventional metal options.2. Durability and Safety:Unlike conventional metal rings, black silicone rings are incredibly durable and can withstand extreme conditions. They are resistant to scratches, dents, and deformation, making them an excellent choice for those engaged in manual labor or high-impact sports. Additionally, black silicone rings are non-conductive, making them safe for individuals working with electricity.3. Comfort and Versatility:Black silicone rings are known for their exceptional comfort. They are lightweight and flexible, ensuring a snug fit without compromising comfort during physical activities. Moreover, these rings offer a wide range of sizes and widths, allowing them to be easily customized to meet individual preferences and style choices.4. Medical Benefits:Another significant advantage of black silicone rings is their suitability for individuals with allergies or sensitive skin. These rings are hypoallergenic, making them an ideal alternative for those who cannot wear metal rings due to potential skin irritations. The medical community has welcomed the use of black silicone rings as a safe and comfortable option for individuals requiring non-metallic jewelry.5. Style and Design:Black silicone rings are not just practical; they are also highly fashionable. They come in a variety of designs and patterns, catering to diverse tastes and preferences. From sleek and minimalistic designs to bold and vibrant patterns, there is a black silicone ring to suit every individual's style. Moreover, these rings are often paired with other materials like wood, carbon fiber, or even precious metals, offering a unique and fashionable look.6. Environmental Consciousness:Black silicone rings align with the growing movement towards eco-friendly and sustainable products. Silicone is a recyclable material, making these rings a greener alternative to metal jewelry. Furthermore, silicone rings require fewer resources and energy to manufacture compared to traditional metal rings, reducing their carbon footprint.Conclusion:Black silicone rings have experienced a surge in popularity due to their versatility, durability, comfort, and style. Their practicality makes them a preferred choice for individuals with active lifestyles, while their hypoallergenic nature broadens their appeal to those with skin sensitivities. With their wide array of designs and eco-friendly credentials, black silicone rings are set to become a mainstay in the world of jewelry. So, why not embrace this stylish trend and discover the perfect black silicone ring to complement your active lifestyle?

Non-Stick Coating Material Accused of Toxicity in North Denver

The Power of O-Rings: How They Keep Our Industries Running SmoothlyWhen it comes to keeping our industries running smoothly, little things often make a big difference. One of these little things is the humble O-ring. You may not have heard of it before but it’s a small but essential component that’s used in many applications, from aerospace and automotive to medical equipment and industrial machinery.An O-ring is a circular ring made of elastomeric material, designed to create a tight seal between two surfaces. It’s often used in hydraulic and pneumatic systems, where it acts as a sealant to prevent fluid or gas leakage. One of the most popular materials used to make O-rings is Teflon, a brand name for polytetrafluoroethylene (PTFE).Teflon O-rings are widely used due to their unique properties. They have high resistance to heat and chemicals, excellent mechanical strength and they’re non-stick, meaning they’re self-lubricating. This makes them ideal for harsh environments, such as those found in chemical processing plants and oil refineries.One of the most common applications of Teflon O-rings is in sealing mechanical equipment. For example, they’re used in hydraulic cylinders to maintain pressure and prevent leaks. They’re also used in engines and pumps to ensure the smooth flow of liquids and gases.Another important application of Teflon O-rings is in the aerospace industry. They’re used in aircraft engines to provide an airtight seal between the engine components, preventing the escape of hot gases and preventing debris from entering the engine. They’re also used in space exploration, where they help to maintain the integrity of the spacecraft’s pressure vessel.Medical equipment is another area where O-ring seals are essential. Teflon O-rings are used in medical devices such as syringes, insulin pumps, and heart valves. They provide a secure seal and are biocompatible, meaning they’re not toxic to human tissue.Despite their tiny size, O-rings play a crucial role in keeping our industries moving smoothly. They’re a simple but incredibly effective solution to many sealing and fluid transfer problems. And when it comes to choosing the right O-ring material for your application, Teflon is often the best choice.So whether you’re designing a new mechanical system, repairing an engine, or developing a medical device, Teflon O-rings are a reliable and long-lasting solution. They may be small, but they’re mighty.

Polyurethane Seals witness hike in demand across industries" can be rewritten as "Demand for quality polyurethane seals surges in multiple industries".

Polyurethane Seals: The Future of Sealing TechnologySealing technology is crucial in various industries, from aerospace to automotive to heavy machinery. In order to keep various fluids and gases contained, high-quality seals are necessary. One of the top sealing materials available on the market is polyurethane seals. These seals are strong, durable, and able to withstand extreme temperatures and pressures. In this article, we will introduce a leading manufacturer of polyurethane seals and discuss the benefits of this revolutionary sealing material.Polyurethane (PU) seals are made from a specific type of polymer and are ideal for demanding applications. These seals can be used in a range of industries, such as oil and gas, mining, marine, and construction. PU seals are resistant to abrasion, wear, and tear, making them highly effective in high-stress environments. They can also be used with various types of fluids, from water to hydraulic oil to corrosive chemicals.One of the key advantages of polyurethane seals is their ability to perform in extreme temperature conditions. Unlike other sealing materials, such as rubber or silicone, PU seals can withstand temperatures as low as -65°C and as high as 120°C. This makes them suitable for use in extreme weather conditions, such as Arctic or desert environments.Polyurethane seals are also known for their durability. They can withstand high pressures and are resistant to deformation and degradation even after prolonged use. As a result, PU seals require less maintenance and have a longer life span than other types of seals. This ultimately saves companies time and money by reducing the need for repairs and replacements.Leading the way in the polyurethane seal industry is the company established in 2001. This company has been manufacturing high quality PU seals for nearly 20 years and has gained a reputation for being a trusted supplier to various industries. Their seals are made using advanced machinery and rigorous quality control processes to ensure they meet the highest standards of performance and reliability.The company's PU seals come in a range of shapes and sizes, from piston and rod seals to wipers and guide rings. They also offer custom designs to meet specific customer requirements. Their seals are compatible with various types of fluids, making them versatile and suitable for a wide range of applications.In addition to their high-quality products, the company prides itself on providing excellent customer service. They work closely with their customers to understand their needs and provide tailored solutions that meet their specific requirements. They also offer technical support and advice to assist customers in selecting the right seals for their applications.The company's commitment to quality and customer satisfaction has led to long-standing relationships with various industries. They have supplied seals to companies in the oil and gas, mining, marine, and construction sectors, among others. Their seals have been used in a range of applications, from offshore oil rigs to mining equipment to drilling machines.Polyurethane seals are the future of sealing technology, offering superior performance, durability, and versatility. As one of the leading manufacturers of PU seals, this company is at the forefront of this revolutionary material. With their high-quality products and exceptional customer service, they are well-positioned to continue meeting the sealing needs of various industries for years to come.

Discover the Benefits of Durable Solid Rubber Balls in Various Applications

Title: Eco-Friendly Rubber Balls: A Sustainable Innovation in the Toy IndustryIntroduction:Rubber balls have been a beloved toy for generations, bringing joy to children and adults alike. However, the manufacturing process and materials used in traditional rubber balls often raise concerns about their environmental impact. In an effort to address these concerns, a leading toy manufacturer, hereinafter referred to as the company, has introduced an innovative and sustainable alternative: the Solid Rubber Ball.1) The Solid Rubber Ball: An Overview (150 words)The Solid Rubber Ball is a groundbreaking eco-friendly toy that aims to revolutionize the toy industry. This innovative product is manufactured using a unique blend of natural, sustainably-sourced rubber, ensuring minimal environmental impact throughout its lifecycle. By eliminating harmful synthetic materials found in traditional rubber balls, the Solid Rubber Ball is a safer and more sustainable choice for consumers.2) Sustainable Manufacturing Process (150 words)The Solid Rubber Ball is manufactured using state-of-the-art technology and a highly sustainable production process. The company has implemented various measures to minimize energy consumption and waste generation. For instance, water used in the production process is recycled and treated, reducing water usage significantly. Additionally, the use of renewable energy sources has been prioritized to power the manufacturing facilities. These efforts result in a reduced carbon footprint and demonstrate the company's commitment to sustainable manufacturing practices.3) Environmentally Conscious Material Sourcing (150 words)One key aspect that sets the Solid Rubber Ball apart is its environmentally conscious material sourcing. The company ensures that the rubber used in the production of these balls is obtained from sustainable plantations, where trees are carefully managed to maintain their health and growth. This holistic approach to material sourcing guarantees a minimal ecological impact, while also providing local communities with fair and ethical employment opportunities.4) Product Safety and Durability (150 words)Apart from being an eco-friendly option, the Solid Rubber Ball also prioritizes consumer safety. Rigorous testing and quality control procedures are in place to ensure that the product meets the highest safety standards. The ball is free from harmful chemicals, making it a safe choice for children and pets. Additionally, its sturdy construction ensures durability, guaranteeing a longer lifespan and reducing waste.5) Environmental Impact and Benefits (150 words)By choosing the Solid Rubber Ball, consumers contribute to a significant reduction in their ecological footprint. The use of sustainably-sourced materials and the elimination of synthetic components greatly decrease the release of harmful chemicals into the environment. Furthermore, the eco-friendly production process minimizes energy consumption and lowers carbon emissions. Ultimately, these factors combined make the Solid Rubber Ball an environmentally conscious choice that supports a healthier planet.Conclusion (50 words)With its focus on sustainability, safety, and durability, the Solid Rubber Ball is a game-changer in the toy industry. Its cutting-edge manufacturing process, responsible material sourcing, and minimal environmental impact make it a leading example of how innovation can be combined with sustainability to create a better and brighter future.Note: The content provided here is a general framework to write an 800-word news article. Feel free to add, remove, or modify the content according to your requirements and available information.

New High-Performance O Rings Made from PTFE Material Now Available

Title: Industry-Leading Company Introduces Cutting-Edge PTFE O Rings in Response to Growing Market DemandIntroduction:In today's rapidly evolving technological landscape, companies are constantly striving to meet the demands of various industries by providing innovative and high-quality solutions. One such company, renowned for its excellence in the manufacturing sector, is set to revolutionize the sealing industry with the introduction of its advanced PTFE O Rings.Body:1. Overview of the Company:The mentioned company, a pioneer in manufacturing industrial components, has been at the forefront of innovation for over two decades. With a commitment to providing top-notch products and services, they have earned a reputation for excellence and reliability. Known for their dedication to customer satisfaction, they have established a wide-reaching network of clients across multiple industries.2. Understanding PTFE O Rings:PTFE (Polytetrafluoroethylene), commonly recognized by its well-known brand name, is a versatile material widely used in various applications. PTFE O Rings, specifically, are critical components that provide efficient sealing solutions in a multitude of industries. Due to their excellent chemical resistance, high thermal stability, and low friction properties, these O Rings have gained immense popularity.3. Unveiling the Advantages of PTFE O Rings:a) Chemical Resistance: PTFE O Rings offer exceptional resistance to a wide range of chemicals, making them ideal for applications in aggressive and corrosive environments. This resistance ensures longevity and reliability in demanding industries such as pharmaceuticals, petrochemicals, and chemical processing.b) Temperature Stability: With an exceptional thermal stability range of -200°C to +260°C, PTFE O Rings maintain their sealing capabilities even in extreme temperature conditions. This flexibility makes them invaluable in various industries, including aerospace, automotive, and food processing.c) Low Friction Properties: PTFE O Rings possess inherent low-friction characteristics, reducing frictional wear and enabling efficient seal performance. This quality makes them an excellent choice for high-speed rotating machinery, such as pumps, compressors, and hydraulic systems.d) Sealing Precision: PTFE O Rings are designed to provide a precise and reliable seal, ensuring leak-free operations. This precision makes them highly suitable for critical applications in the medical, pharmaceutical, and semiconductor industries, where leakage can have severe consequences.4. Committed to Quality and Reliability:The company's commitment to quality and reliability is evident in their state-of-the-art manufacturing facilities equipped with cutting-edge machinery. By utilizing advanced production techniques and adhering to stringent quality control processes, they ensure that each PTFE O Ring meets the highest industry standards and customer expectations.5. Catering to Diverse Industries:Recognizing the diverse needs of various industries, the company offers a wide range of PTFE O Rings tailored to specific requirements. Whether it is dimensions, tolerances, or specialized materials, they cater to the unique demands of industries such as oil and gas, pharmaceuticals, automotive, aerospace, electronics, and many more.6. A Greener Future:In line with their commitment to environmental sustainability, the company ensures that all their PTFE O Rings are manufactured using eco-friendly processes. By minimizing waste generation and adopting sustainable practices, they contribute to a greener future, aligning their products with the growing global focus on sustainability.Conclusion:The unveiling of the company's advanced PTFE O Rings marks a milestone in the sealing industry. With their exceptional chemical resistance, temperature stability, low friction properties, and precise sealing capabilities, these O Rings are set to become the go-to choice for industries seeking reliable sealing solutions. As the market demand for high-performance sealing components continues to grow, the company's commitment to quality and innovation ensures that they remain at the forefront, empowering businesses to achieve uninterrupted operations and enhanced efficiency.